Expansion joints

Our joints are designed to withstand the highest levels of traffic load in circulation today as well as exposure to pollution, oil and road deicing salts. Their extreme durability and easy replacement make them the most cost-effective choice in the long run.

VIAJOINT is an expansion joint with a maximum movement of 20 mm. It suits all types of road surfaces and requires no maintenance, under any traffic conditions whatsoever. It is made up of a bitumen-elastomer binder containing granular aggregates, to provide mechanical resistance under the traffic load, and an aluminum joint gap cover, to prevent corrosion problems.

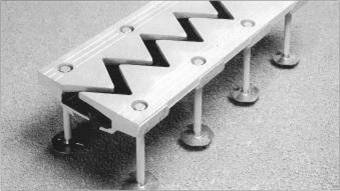

The CIPEC range is suited to handle movements from 30 to 1000 mm regardless of the type of bridge deck, installation or operating conditions. They are made of metallic elements, an anchor system and a continuous elastomer sealing section. In this category we have three types of joints:

- Small movement expansion joints (JEP, WR and WOSd)

- Medium movement expansion joints (Wd)

- Large movement expansion joints (WP)

Each category is also adapted to a certain traffic load.

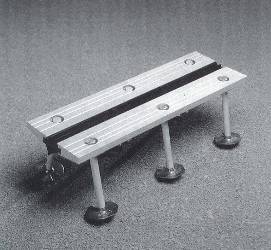

The MULTIFLEX joints are flexible bridge expansion joints in which the thrust caused by the structure is taken up by the deformation of the elastomer parts. MULTIFLEX joints are made of molded elastomer elements, vulcanized and bonded to metal inserts designed to take up the running loads and distribute attaching forces.

The range caters to two types of design:

- single module joints (N50, S80, S100, S150)- with this type of joint, the gap is bridged by a central insert supported by two elastomer strips absorbing the applied deformations. This design covers the movement range up to 150 mm.

- bridged joints (S200, S250, S350)- with this type of joint, gap bridging and deformation functions have been separated. The joints address the movement range included between 200 and 350 mm.

Download C V 1_Freyssinet expansion joints En v02

Download C V 1_Freyssinet expansion joints En v02

Advantages in using our joints:

- excellent traffic control;

- long life;

- low noise;

- high corrosion resistance;

- no horizontal reaction;

- protection of surface under joints;

- good resistance to heavy duty & frequent traffic loads;

- adaptability to all types of surface structure;

- easy installation – the modulus joints (1 m long elements) can be installed and replaced without traffic interruption;

- low servicing & maintenance;

- easy and quick replacement (without damaging the existing structure).